Siemens Review 2025

Siemens CAD Plans & Pricing

Siemens Comparison

Expert Review

Pros

Cons

Siemens CAD's Offerings

To get information on pricing, you have to either contact a sales representative, find a solution partner near you or buy from their online store. You can choose to purchase, subscribe or download any of their software. The subscription plan is available monthly or annually, depending on the most convenient for you. Siemens software pricing is a bit pricey compared to other software-providing companies.

Customer Support

The team at Siemens is available via email and phone 24/7 every day. They also provide training to give you more understanding of how to use the software. There’s also an inquiry page where you submit your data and message.

Features & Functionality

Design Features

Here are the top features of Siemens CAD and design software, showcasing the extensive capabilities offered to enhance product development and engineering workflows:

- NX CAD: modeling, drafting & simulation

- Solid Edge: 2D drafting and 3D design

- NX CAM

- Solid Edge electrical design

- NX for additive manufacturing

- Solid Edge Simulation

- NX design validation

- Solid Edge data management

- Solid Edge generative design

- NX value-based licensing

- Solid Edge additive manufacturing

- NX model-based definition (MBD)

- Solid Edge technical publications

- Compliance management

- Business reporting

- Design management

- Product data management

- Supplier management

Let’s explore them in more detail:

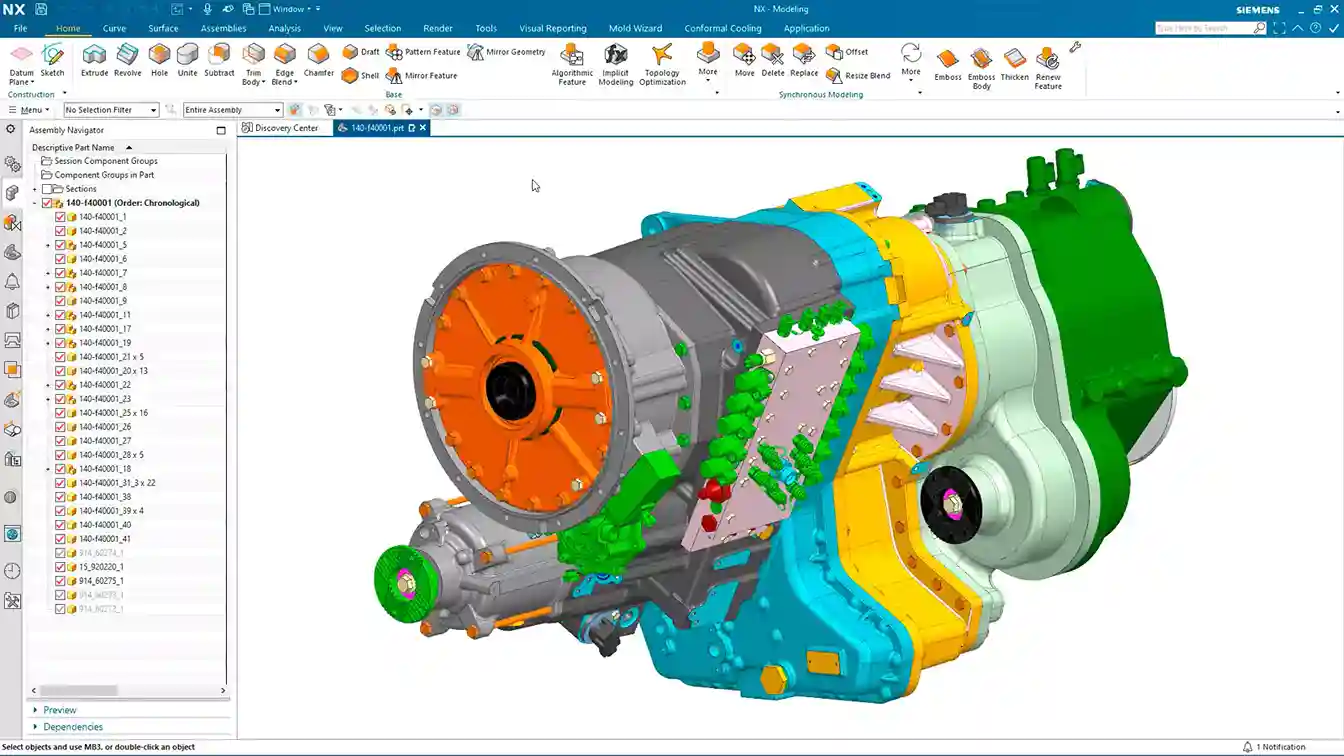

NX CAD

NX CAD provides a comprehensive suite of CAD tools for mechanical design, covering every aspect of product development. It supports modeling, drafting, and simulation, enabling seamless collaboration and high-quality design output.

The platform’s integration with CAM ensures that designs can be directly manufactured with minimal transition. NX CAD also incorporates advanced features like generative design, model-based definition, and design validation, significantly boosting design efficiency and reducing time-to-market.

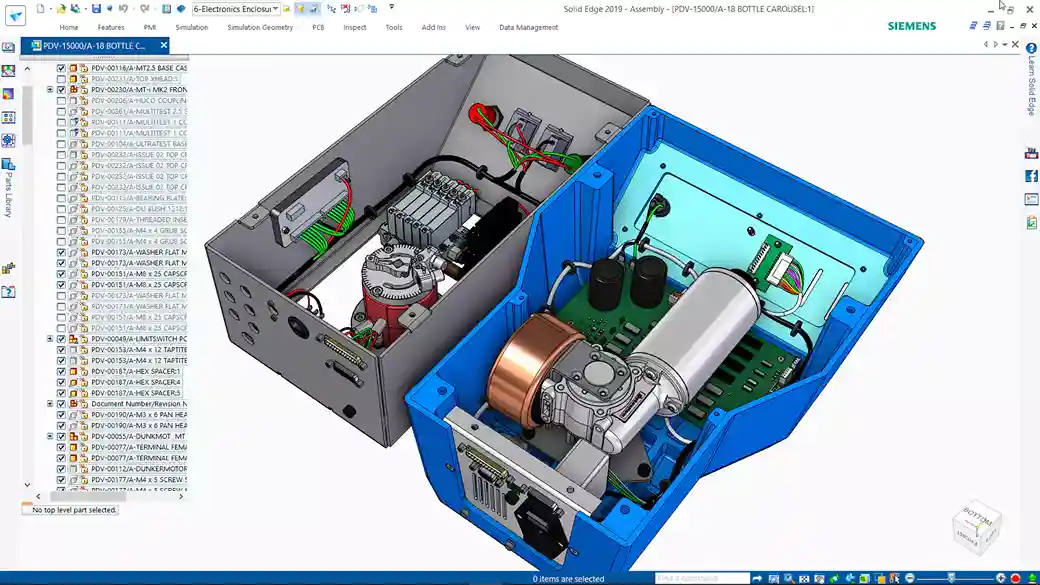

Solid Edge

Solid Edge is a versatile CAD tool that combines synchronous technology with traditional modeling techniques. It supports both 2D drafting and 3D design, offering tools for mechanical and electrical design, simulation, and manufacturing.

Solid Edge includes features such as generative design, point cloud visualization, and advanced motion simulation, making it ideal for a wide range of engineering applications. Its user-friendly interface and low-cost subscription model make it accessible for startups and small businesses.

NX CAM

NX CAM is an integrated solution for part manufacturing, providing tools for CNC machining, additive manufacturing, and quality control. It allows users to program complex machining operations directly from CAD models, ensuring high precision and efficiency.

NX CAM supports various manufacturing processes, including milling, turning, and multi-axis machining, and integrates with Siemens’ digital twin technology to enhance process optimization and reduce production time.

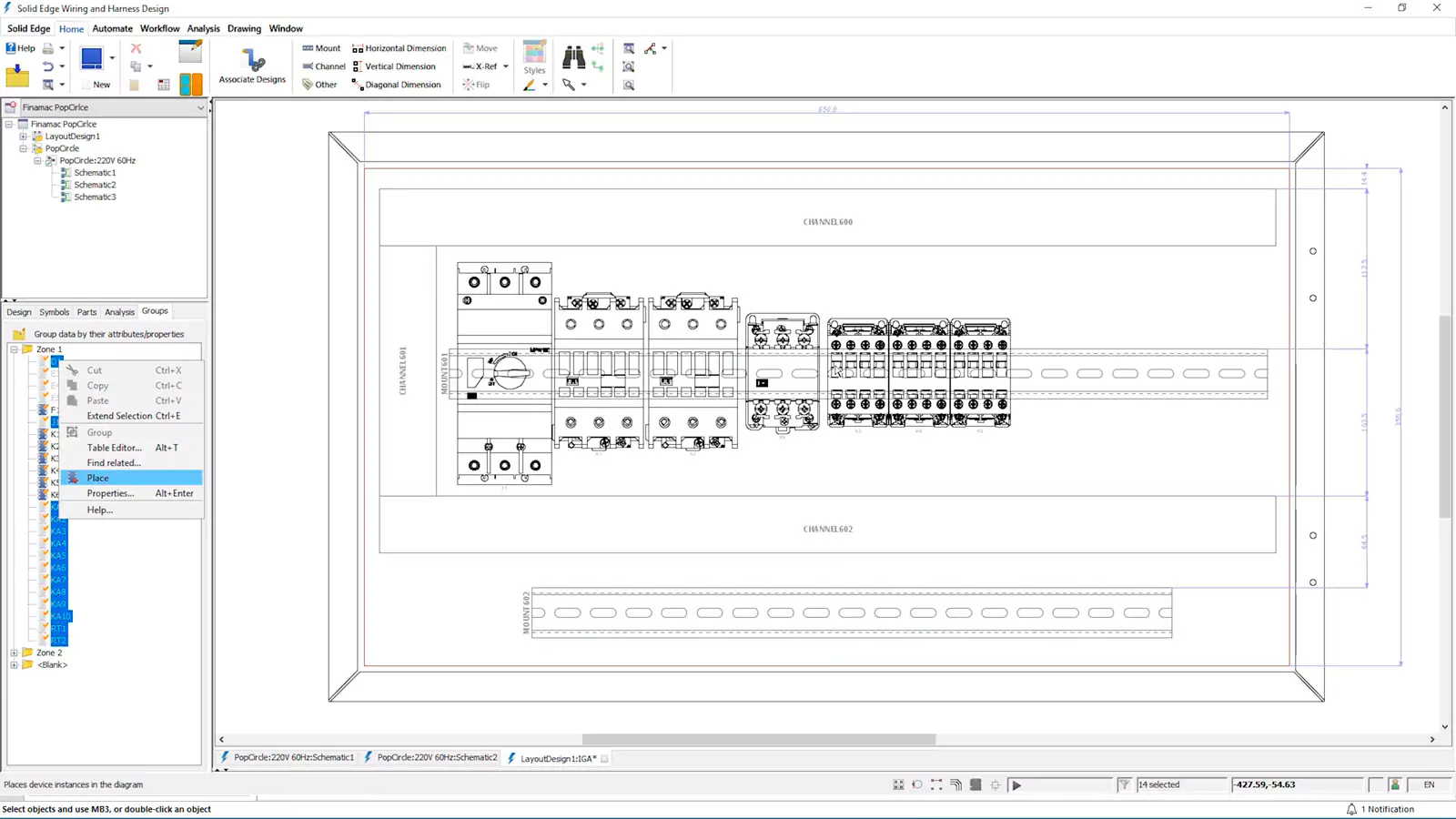

Solid Edge Electrical Design

The Solid Edge Electrical Design tool offers a comprehensive set of features for creating and managing electrical systems within mechanical designs. It includes schematic capture, wiring, harness design, and PCB collaboration.

These features enable electrical engineers to design complex systems efficiently and ensure seamless integration with mechanical components, enhancing overall product quality and reducing development time.

NX for Additive Manufacturing

NX for Additive Manufacturing provides advanced tools for designing, optimizing, and building components using 3D printing technologies. It supports both metal and plastic additive manufacturing processes and integrates with NX CAD for seamless design-to-production workflows. This feature allows engineers to create complex geometries that are difficult or impossible to produce with traditional manufacturing methods, reducing material waste and production costs.

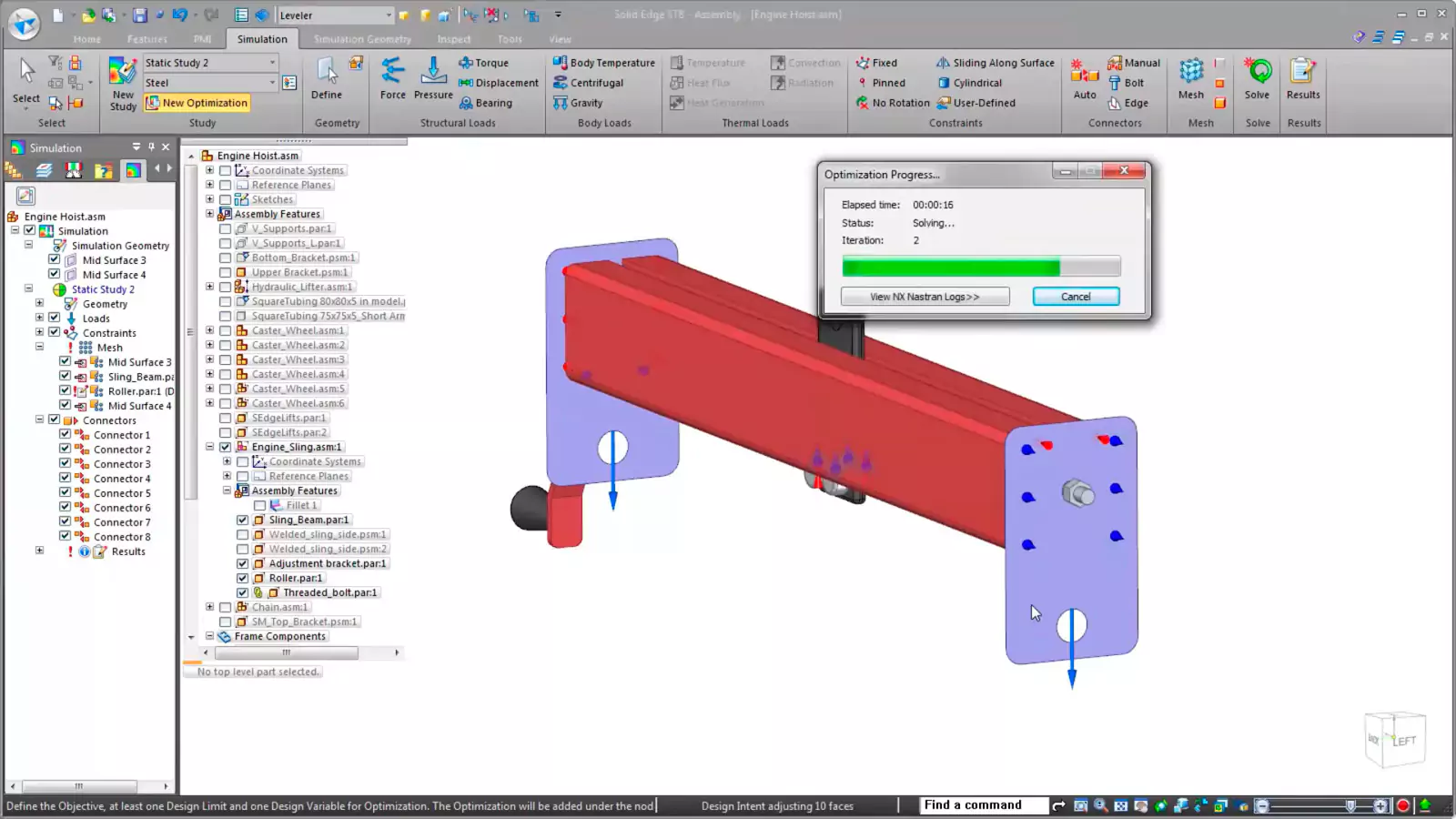

Solid Edge Simulation

Solid Edge Simulation offers robust tools for performing structural, thermal, and motion analysis on parts and assemblies. It includes linear stress simulation, advanced motion simulation, and simulation optimization, allowing engineers to validate and optimize designs before manufacturing.

This reduces the need for physical prototypes, saving time and costs while ensuring that the final product meets performance requirements.

NX Design Validation

NX Design Validation provides tools for visual product analytics and compliance checking, enabling designers to ensure that their designs meet all necessary requirements and standards. It includes features for checking geometric dimensioning and tolerancing (GD&T), performing interference checks, and validating assemblies. This helps in identifying potential issues early in the design process, reducing the risk of costly errors and rework.

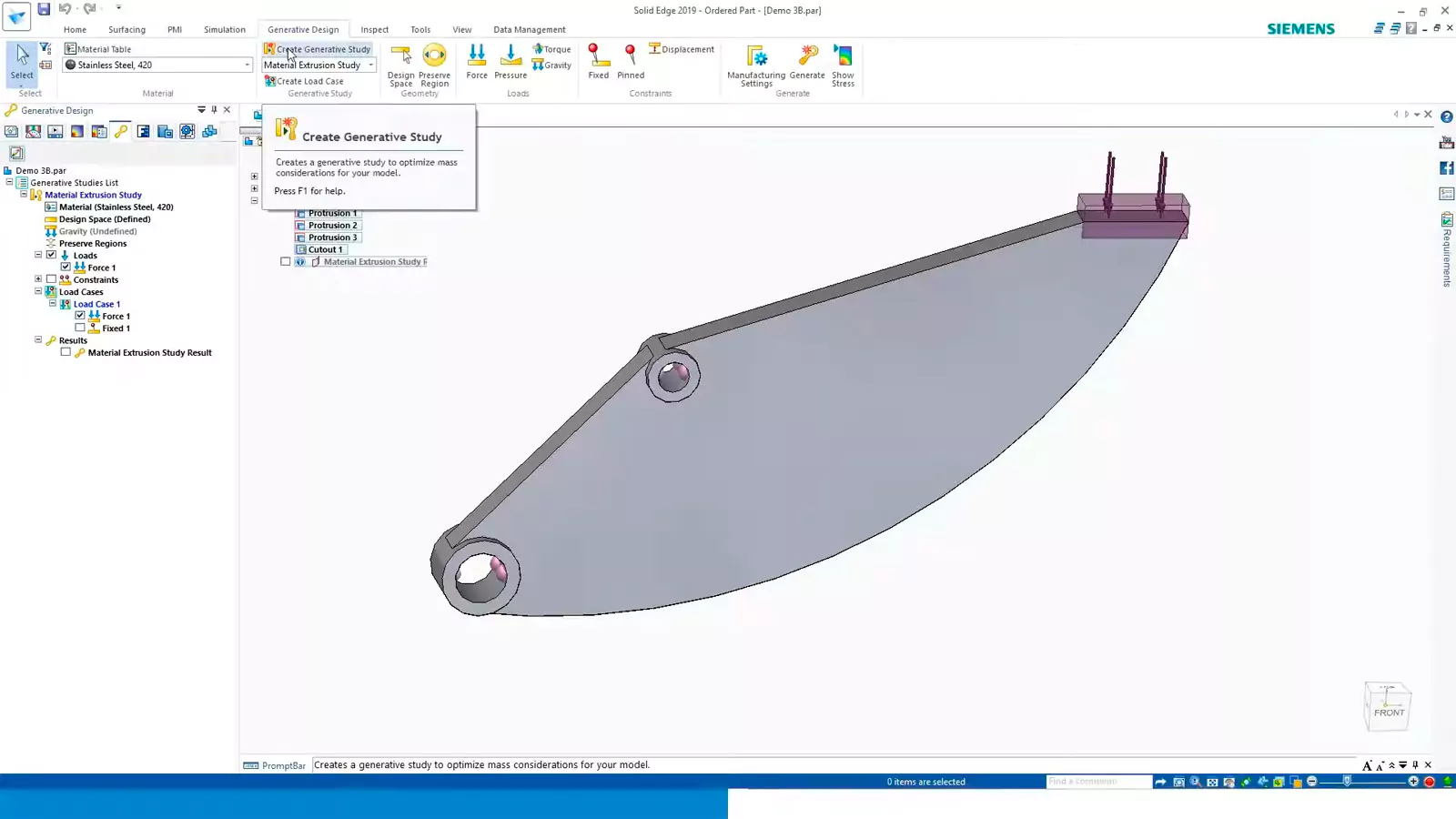

Solid Edge Generative Design

Solid Edge Generative Design allows engineers to create optimized designs based on specified constraints and requirements. This tool uses algorithms to explore a vast array of design possibilities, identifying the most efficient and innovative solutions. It helps in reducing material usage and weight while maintaining strength and functionality, significantly enhancing the overall design process.

NX Value-Based Licensing

NX Value-Based Licensing offers a flexible licensing model that allows users to access a wide array of CAD and CAM tools through a token-based system. This system provides cost-effective access to various modules and features as needed, enabling companies to scale their capabilities without large upfront investments. This flexibility supports dynamic project needs and optimizes software utilization.

Solid Edge Additive Manufacturing

Solid Edge Additive Manufacturing provides tools for designing, simulating, and optimizing parts for 3D printing. It integrates with various 3D printers and supports both metal and plastic additive manufacturing processes. This feature helps engineers to innovate with complex geometries and rapid prototyping, reducing the time and cost of product development.

NX Model-Based Definition (MBD)

MBD enables the creation of fully annotated 3D models that include all the necessary information for manufacturing and inspection. This eliminates the need for traditional 2D drawings, streamlining the workflow and reducing errors. MBD supports digital twin initiatives by ensuring that all product data is accurately represented and easily accessible throughout the product lifecycle.

Solid Edge Technical Publications

These publications provide tools for creating detailed and interactive documentation directly from CAD models. This includes assembly instructions, maintenance manuals, and user guides. Leveraging the CAD data ensures that the documentation is accurate and up-to-date, enhancing the quality and usability of the final product documentation.

Compliance Management

Bills of Material Management –For the integration of materials and substances into the aerospace platform.

Compliance Grading and Reporting –You can use the software for grading aerospace platforms for compliance against social and environmental regulations such as REACH and custom rules.

Sustainability Framework –You can use a sustainability framework to control aerospace environmental compliance with the support of BOM grading and eco-design processes.

Bill of Materials Management–Helps you integrate materials and substances for use in the aerospace platform.

Business Reporting

Business Intelligence and Reporting –For easier measurement, analysis, and report of key performance metrics for your products improvement. Also, for a report on sustainability and supplier disclosure status.

Design Management

Sharing of relevant data –using the software helps you search and establish proper design context quickly. You can easily navigate through a large amount of product information and work with only relevant data.

For collaboration, validation, and re-use of data– Multi-CAD management helps to abolish all error-prone due to the process of translating data from several tools for use in your design environment.

Mechanical Design Integration –Designers can use the software directly from their mechanical CAD tool for accessing live information.

Product Data Management

Secure Data Management –PDM system helps to capture and manage product information by ensuring that information is delivered to users throughout the product lifecycle in the best way possible.

Configuration Management – provides the necessary visibility for managing and presenting lots of materials.

Supplier Management

Direct Materials Sourcing – With this, you will be able to understand what drives cost soon enough in the product’s lifecycle and understand the impact of the supply chain before changes are approved.

Supplier Collaboration – you are able to extend your product’s lifecycle management processes to your suppliers efficiently with the use of real process integration.

Collaboration

Work seamlessly with teams using shared design tools.

Construction

Transform designs into real-world projects with construction-oriented features.

Ease Of Use:

Siemens has made tutorials available to guide you through step-by-step on how to use their products and services. You also get to have access to a wide range of apps, preinstalled template tools, and APIs in Mendix for better productivity. All these make it easy to use the software. If you encounter more issues on how to use it, you can contact their consultant and they will proffer solutions to it.

Verdict:

The software has an amazing user interface and a lot of capability to help manage large assembly and data management. Teamcenter can be configured to suit all corporate organizations.