EspritCAM Review 2025

EspritCAM CAD Plans & Pricing

EspritCAM Comparison

Expert Review

Pros

Cons

EspritCAM CAD's Offerings

Esprit pricing plans are not available online. You can contact Esprit to get a custom or quote-based plan.

Customer Support

Esprit prides themselves in their fast and effective customer support. There are help files available for the esprit interface and the support team is always on hand to respond to any query sent via web contact form or email, with a 30min or less response time.

Additional support includes:

Community Forum:

This software does have learning, training, and a Facebook community.

Blog:

Esprit has a blog where they post world and product announcements

Features & Functionality

Design Features

Used across various industries, EspritCAM is a powerful software that supports every CNC machine type and configuration. Not only that, this software allows you to maximize the full potential of your machine capabilities with numerous unique features:

- 2- to 5-axis milling

- 2- to 22-axis turning

- 2- to 5-axis wire EDM

- Swiss-type, mill-turn, and B-axis multitasking machines

- High-speed simultaneous 3-, 4-, and 5-axis toolpath

- Production turning, multi-turret, and multi-spindle solutions

- On-machine inspection (probing)

- Additive direct energy deposition

- Turn-key post processors and edit-free G-code

- Workflow automation

- Profit milling cycles

- Production machining

- Digital twin simulation

- Rendering in 3D

- Editing with a WYSIWYG editor

- Collaboration capabilities

- File import/Export

Here is an in-depth look at some of these features:

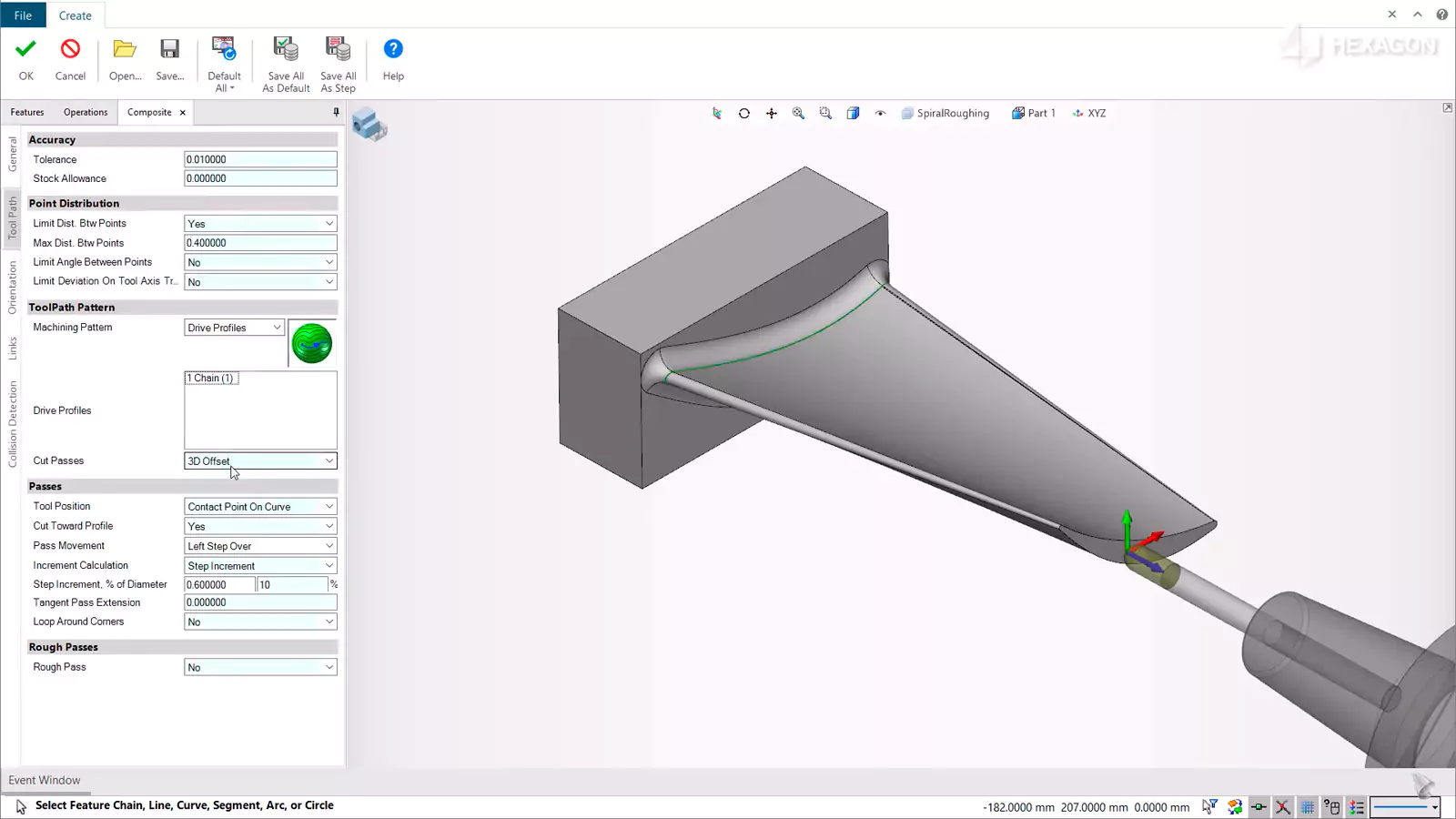

2- to 5-axis milling

ESPRIT CAM supports 2- to 5-axis milling, offering precise and efficient milling solutions for a variety of complex geometries. This capability enables high-quality machining with greater flexibility and control, making it suitable for industries requiring detailed and accurate parts, such as aerospace and automotive.

2- to 22-axis turning

The CAD software supports a wide range of turning operations, from 2-axis to 22-axis turning, allowing for the machining of intricate components with multiple spindles and turrets. This feature ensures efficient production of complex turned parts, enhancing productivity and reducing setup times.

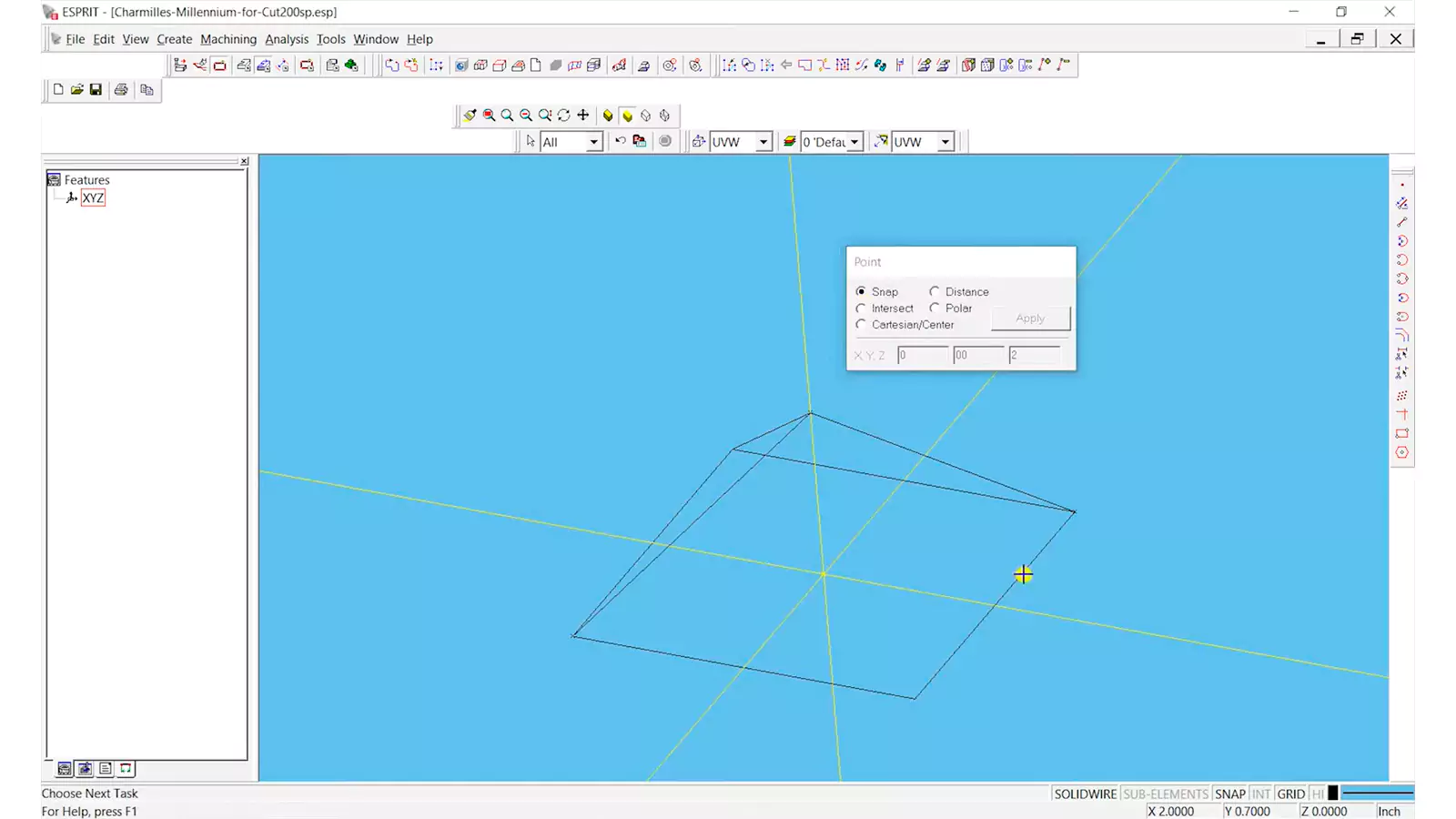

2- to 5-axis wire EDM

ESPRIT CAM’s wire EDM capabilities cover 2- to 5-axis operations, providing precise control for cutting complex shapes with high accuracy. This feature is particularly valuable in industries such as medical device manufacturing, where precision is critical.

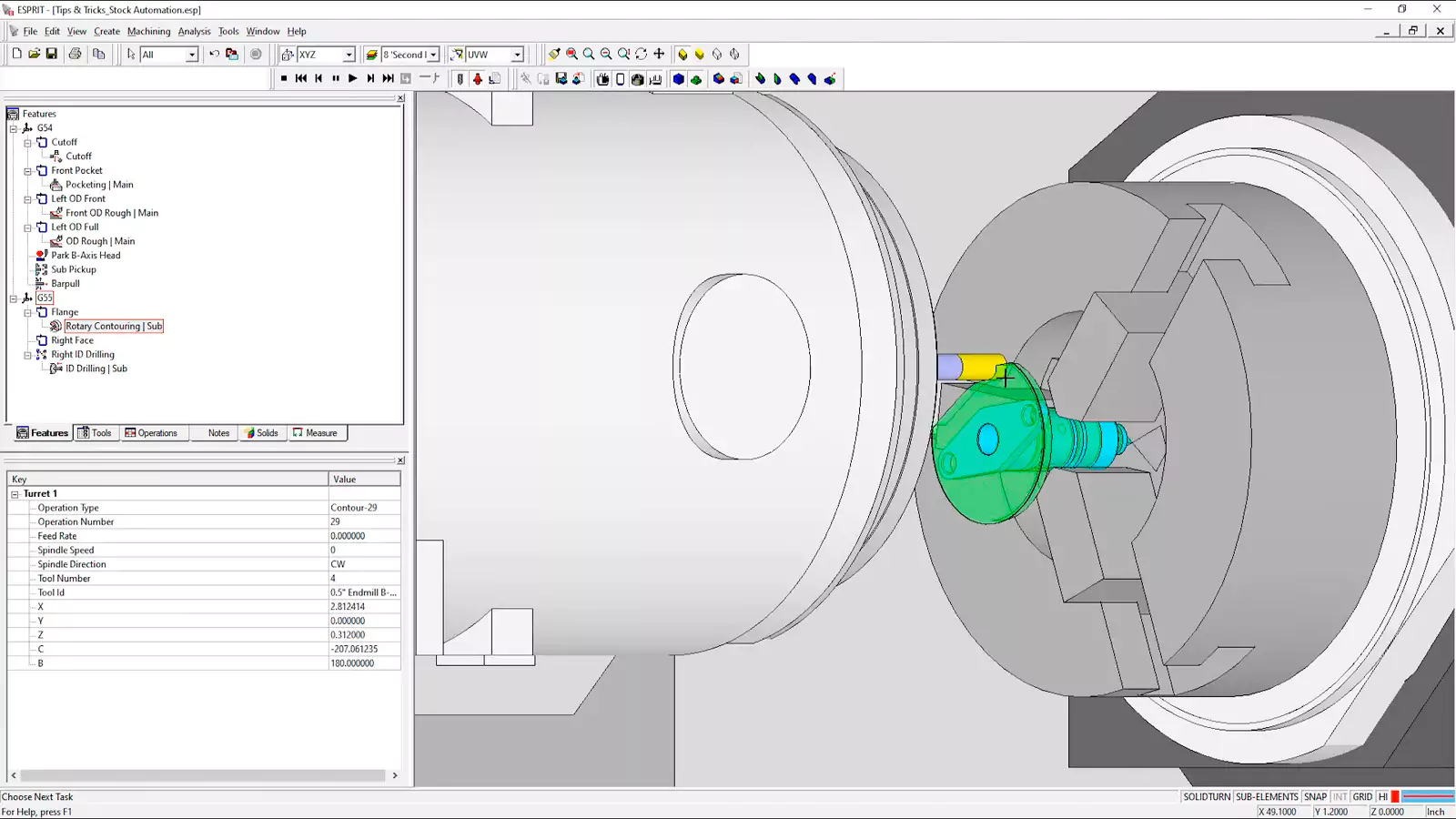

Swiss-type, mill-turn, and B-axis multitasking machines

The CAD tools support Swiss-type lathes, mill-turn, and B-axis multitasking machines, offering comprehensive solutions for complex machining tasks. These capabilities enable the efficient production of small, intricate parts and high-precision components, enhancing flexibility and reducing cycle times.

High-speed simultaneous 3-, 4-, and 5-axis toolpath

ESPRIT CAM provides high-speed simultaneous toolpath capabilities for 3-, 4-, and 5-axis machining, ensuring smooth and efficient operations. This feature allows for faster machining times and improved surface finishes, which is critical for industries that demand high-quality outputs.

Production turning, multi-turret, and multi-spindle solutions

The CAD tools include production turning solutions with multi-turret and multi-spindle configurations, optimizing the machining process for high-volume production. These features help in maximizing machine utilization and reducing overall production costs.

On-machine inspection (probing)

ESPRIT CAM’s on-machine inspection feature allows for real-time probing and inspection directly on the CNC machine. This capability ensures parts are manufactured to exact specifications, reducing the need for separate quality control processes and minimizing errors.

Additive direct energy deposition

The software supports additive manufacturing through direct energy deposition, enabling the creation and repair of metal parts with high precision. This feature integrates seamlessly with traditional subtractive processes, offering a complete solution for hybrid manufacturing environments.

Turn-key post processors and edit-free G-code

ESPRIT CAM is known for its turn-key post processors and the ability to generate edit-free G-code. This feature simplifies the programming process and ensures reliable machine operations. It reduces the need for manual code adjustments, saving time and minimizing errors.

Workflow automation

ESPRIT CAM offers workflow automation tools that eliminate repetitive tasks and streamline the flow of data within the CAM system. By leveraging the software’s API, users can customize automation solutions to fit their specific needs, enhancing productivity and reducing manual intervention.

Profit Milling Cycles

One of its powerful features is its patented profit milling cycles which increases the speed of your machining cycles, and in turn, reduces cycle time and ultimately increases overall tool life. Also, the 5-axis deburring cycles included in your program significantly reduce the need for human intervention.

Production Machining

You can dynamically change your project by editing your master workpiece. This is made possible by the automatic synchronization of multiple workpieces with the master workpiece. This results in reduced cycle time as tool changes, axis rotation, and machine travel are significantly kept at a minimum.

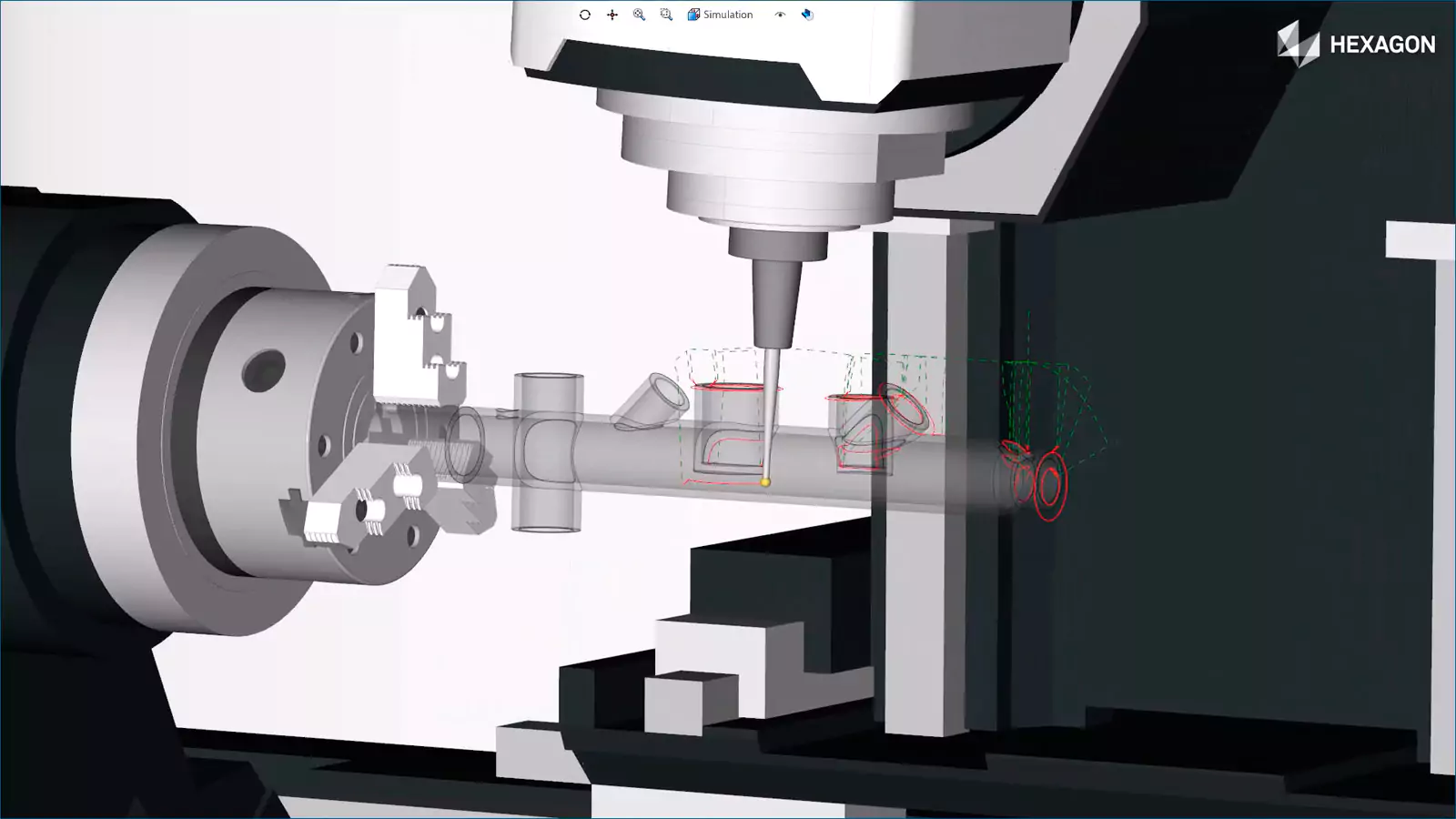

Digital Twin Simulation

Additionally, Esprit optimizes machining processes using a unique twin simulation feature. This involves the creation of a digital replica of the machining environment. the digital twin moves and operates exactly like the original machine set up. This way, machine users can drastically reduce machine setup time.

Rendering in 3D

ESPRIT CAM’s rendering capabilities allow users to produce detailed 3D visualizations directly within the software, without the need for integrating third-party hardware.

This feature enables designers to create realistic representations of their projects, facilitating better visualization and understanding of complex geometries and machining processes.

Collaboration capabilities

ESPRIT CAM enables multiple users to save and share work within a single project, enhancing teamwork and efficiency. This feature allows real-time synchronization of changes, reducing errors and streamlining workflows, making it ideal for remote teams and complex projects.

File import/Export

Esprit allows you to import 2D and 3D models into its interface for your users to edit and collaborate as needed.

Collaboration

Work seamlessly with teams using shared design tools.

Ease Of Use:

Generally, Esprit is easy to use. It has a standard design software interface with a tabular menu structure. The functions of each tab and what you can do with each option are listed underneath each, making the software relatively easy to understand and use. However, there are tons of features as well as buttons, and this can be overwhelming for inexperienced designers.

Verdict:

Overall, Esprit is a great CAD/CAM software. its CAD to CAM interface makes it a go-to option for satisfying CAD/CAM needs. With this interface, users can reduce design time, as there’s no need to rebuild or edit the geometry of native parts models, they can import straight from the source. However, as the name implies, EspritCAM is more CAM than CAD. And with numerous unique features like twin simulation, multitasking, 5-axis deburring, etc., this software solution is adaptable for any type of machining process. Also, the partnership with Onshape to create a full cloud-based CAD allows for easy collaboration between users, even on different devices.