10 Smart Ways to Improve Your Inventory Management Process

If you run a small business, inventory can either be your best friend—or a silent profit killer. Poor inventory control leads to stockouts, wasted money, and unhappy customers. But with a few smart moves, you can tighten your inventory process and grow more efficiently.

Here are 10 effective, practical ways to improve your inventory management and build a system that works for your business.

What is Inventory Management?

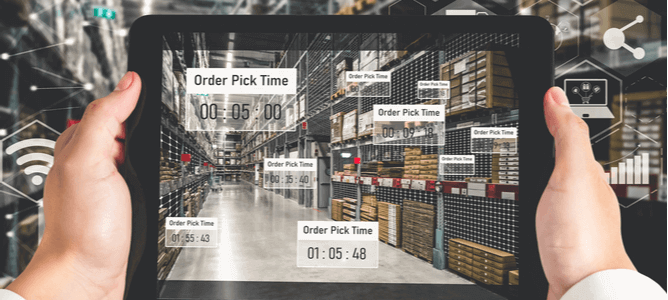

Inventory management comprises processes and practices in the supply and demand chain used to track the amount of stock in the warehouse. The main goal of an inventory management system is to help you identify where inventory is and how much is available to manage the levels appropriately.

An inventory management system is different from an ERP system as it focuses on the supply chain process. Inventory management systems can integrate with other software such as point of sale, shipping, and channel management.

Best Inventory Management Software

Easily manage orders, shipping & returns

Easily manage orders, shipping & returns  Accurate stock tracking: Barcode & RFID

Accurate stock tracking: Barcode & RFID  Automated stock replenishment feature

Automated stock replenishment feature  Integrate inventory with ERP & suppliers

Integrate inventory with ERP & suppliers  Manage your inventory in bulk

Manage your inventory in bulk  Real-time tracking & item categorization

Real-time tracking & item categorization Benefits of Inventory Management

- Good inventory management improves the supply chain process and enhances reliability.

- It helps to minimize losses due to untraceable sales

- It reduces costs by allowing you to purchase only items that are needed

- It helps keep track of the amount of stock and identify the right time to order more goods

Tips for Improving the Inventory Management Process for Your Company

1. Use Inventory Management Software

The days of spreadsheets are over. Modern inventory software can help you track stock in real time, forecast demand, and even automate reorders.

What to look for:

- Real-time stock levels

- Low-stock alerts

- Barcode scanning

- Sales tracking & forecasting

- Integration with your POS and e-commerce tools

Popular tools for small businesses:

- Systems with simple dashboards and mobile access

- Affordable plans that grow with your needs

- Easy setup without IT support

Pro tip: Even basic software is better than manual tracking. It saves time, cuts errors, and helps you make smarter restocking decisions.

2. Categorize Your Inventory

Not all products are equal. Use a method like ABC analysis to separate items by importance:

- A: High-value, low-volume items

- B: Mid-range value and volume

- C: Low-cost, high-volume items

This helps you prioritize what needs tight control, what you can buy in bulk, and what needs occasional checks.

3. Set Reorder Points and Par Levels

A “reorder point” is the stock level that triggers a new order. “Par level” is the minimum amount you should always keep on hand.

Setting these limits helps you:

- Avoid running out of stock

- Prevent over-ordering

- Plan better with seasonal changes

Modern software can automate this, sending alerts when items hit your custom reorder thresholds.

4. Conduct Regular Inventory Audits

Even with automation, it’s smart to manually check inventory regularly. Choose from:

- Annual full counts

- Cycle counts (check a small portion each week)

- Spot checks when something seems off

Audits catch errors early, uncover shrinkage, and help match your system with reality.

5. Optimize Storage Layout

Messy stockrooms slow everything down. A clean, labeled, and logical layout:

- Reduces pick-and-pack mistakes

- Speeds up fulfillment

- Keeps your team organized

Use tools like barcode labels, storage bins, and clear signage. Group fast-selling products up front and organize slow movers in back.

Related Articles

6. Train Your Team on Best Practices

Your inventory system is only as good as the people using it.

Train staff on:

- How to receive and check new inventory

- Scanning barcodes correctly

- Flagging damaged or misplaced items

Clear processes mean fewer mistakes—and fewer headaches later.

7. Use the FIFO Method (First-In, First-Out)

This principle means selling the oldest stock first. It helps prevent:

- Expired products (especially food or beauty items)

- Obsolete tech or seasonal products

- Accidental overstocking

Organize shelves so older items are easy to reach, and newer ones are placed behind them.

8. Analyze Supplier Performance

Good suppliers are key to great inventory management. Track:

- Delivery speed

- Order accuracy

- Communication quality

If a supplier causes constant delays or mistakes, it may be time to renegotiate—or replace them.

9. Forecast Demand Using Sales Data

Smart forecasting is the difference between excess stock and empty shelves.

Use tools (or reports from your POS/inventory system) to spot:

- Seasonal sales patterns

- Customer buying trends

- Top-selling items by time of year

When you know what’s coming, you can plan smarter and avoid last-minute orders.

10. Embrace Automation and Integrations

Automating parts of your inventory management can save hours and cut errors. Look for systems that integrate with:

- E-commerce platforms

- Accounting software

- Shipping and logistics

This ensures all parts of your business are synced—and your data stays accurate without double entry.

Final Word

Inventory management is an essential aspect for all businesses, regardless of size. However, due to technological advances and changes in consumer preferences, it is advised to use an advanced system. It will help your company keep track of your business operation pattern.

Business owners can adopt different techniques to help improve the inventory management process. These steps make the system more effective and attain the overall business objectives.